Welcome to

TEJASAVI ROLLS INDIA

About us

ONE OF THE LEADING MFRS. & EXPORTERS OF ROLLS!

Tejasavi Rolls India, a leading manufacturer and exporters of rolling mill rolls. With more than 25+ years of experience and expertise, we specialize in providing high-quality and durable rolls for the metal forming industry. Our state-of-the-art manufacturing facilities and skilled technicians ensure that each roll is produced to meet the specific needs of our clients. We are committed to delivering exceptional customer service, and continuously strive to improve our products and processes.

At Tejasavi Rolls India, we are dedicated to delivering premium quality rolling mill rolls to our clients worldwide. Our extensive product line includes rolls for Hot rolling mills , as well as special application rolls for unique requirements. With a focus on innovation and technology, we continuously invest in research and development to ensure that our rolls are at the forefront of the industry. Our team of experts works closely with clients to understand their specific needs and provide customized solutions that improve production efficiency and product quality. Trust us to provide reliable and cost-effective rolls for your mill and elevate your metal forming operations to the next level.

At Tejasavi Rolls India, we understand the importance of reliable and efficient rolling mill rolls to the success of our clients’ operations. That’s why we only use the highest quality raw materials and cutting-edge production techniques to manufacture our rolls. Our rigorous quality control processes and stringent testing ensure that each roll meets or exceeds industry standards.Partner with us and experience the difference that comes with working with a leading provider of rolling mill rolls. Contact us today to learn more about our products and services.

Our products –

SG Iron Rolls

SG Acicular Rolls

Forged Rolls

DPIC Rolls

Adamite Rolls

Reels

Vision

Seek Perfection

-

- At Tejasavi Rolls we passionately believe that work is Religion.

- We strive to seek perfection in all that is done.

- Quality and skill coupled with Versatility and Perfection is what stands for us.

- To be the most reliable manufacturer and service provider in the Rolling Mill industry.

Achieve Excilliency

- To achieve & exceed international standards of excellence in all aspects of business with focus on customer delight through quality products, service and cost reduction.

- To Produce high-quality products, providing related services and solutions to a worldwide client base.

- To earn the trust and confidence of our clients be exceeding their expectations.

- Practice ethics and transparency in all our business operations.

Our Products

Definite Chilled Rolls

Definite Chilled Rolls

Definite chilled iron rolls have a high-hardness layer of white cast iron at the surface.There is no free graphite basically in the matrix of work layer of alloy chilled cast iron roll, so its hardness is high with fine wear-resistant property. It can be used in small bar and wire rod as well as narrow strip steel fine rolling machine stand, and metallographic structure contains fine pearlite and carbide.

Application : Plate, Medium, Narrow Strip, TMT, Wire Rod, Round & Bar.

Range of chemical composition :

| Hardness | C | Mn | Si | P | S | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|

| 50-60 | 3.00/3.30 | 1.10/1.40 | 0.80/1.10 | 0.15-MAX | 0.06-MAX | 1.00/1.50 | 0.80/1.10 | 0.20/0.35 |

| 60-70 | 3.00/3.20 | 0.60/0.90 | 1.00/1.60 | 0.11-MAX | 0.11-MAX | 1.50/2.00 | 1.00/1.60 | 0.30/0.40 |

| 70-75 | 3.00/3.50 | 0.60/0.90 | 0.70/1.10 | 0.10-MAX | 0.050-MAX | 1.50/3.00 | 1.60/1.90 | 0.40/0.50 |

Indefinite Chilled Rolls

Indefinite Chilled Rolls

Indefinite Roll is cast using such proportions of silicon, chromium, nickel and molybdenum that the working face is no longer completely white but contains a small amount of very finely divided graphite flakes gradually increasing from face to core with corresponding decrease in the amount of carbide. The transition from Chill to graphite being more smooth, the gradual change in hardness associated with the indefinite-chill structure allows deeper grooving. Thus Indefinite Chill Rollers are superior in biting performance and have enough strength and resistance against thermal shock occuring at the time of accident in the rolling operation compared to Indefinate Chilled Rolls

Application : Plate, Medium, Narrow Strip, TMT, Wire Rod, Round & Bar.

Range of chemical composition :

| Hardness | C | Mn | Si | P | S | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|

| 70-75 | 3.00/3.40 | 0.60/0.90 | 0.70/1.10 | 0.10-MAX | 0.50-MAX | 1.50/2.50 | 0.20/1.50 | 0.25/0.40 |

| 75-80 | 3.10/3.40 | 0.60/0.90 | 0.70/1.10 | 0.10-MAX | 0.50-MAX | 2.00/3.00 | 0.20/1.50 | 0.30/0.40 |

| 80-85 | 3.10/3.40 | 0.60/0.90 | 0.70/1.10 | 0.10-MAX | 0.50-MAX | 2.00/3.00 | 0.20/1.50 | 0.30/0.40 |

Alloy Steel Base Rolls

Alloy Steel Base Rolls

These Rolls consist of lower carbon materials with some alloying, especially chromium. This range of rolls are capable of a higher strength and wear resistance and are capable of good surface finish. These Rolls are supplied with a carbon content of up to 1.5% and are heat treated to give a hardness which is normally between 30 and 45 degrees Shore C.

Application : Heavy Section, Medium Section, Light Section, Beams, Rail & Bar Mills, Medium & Narrow Strip TMT & Wire Rod Mills, Heavy, Medium & Light Section Mills.

Range of chemical composition :

| Hardness | C | Mn | Si | UTS | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 30-40 | 0.50/1.50 | 0.50/1.00 | 0.60-MAX | 60/75 | 0.40/0.80 | 0.80/1.20 | 0.25/0.40 |

| 40-45 | 1.00/1.50 | 0.50/1.00 | 0.60-MAX | 60/75 | 0.41/0.80 | 0.80/1.20 | 0.30/0.40 |

Double Poured Chill

Double Poured Chill

The working surface of Double Poured Chilled Rolls . shows the white graphite free structure consisting of eutectic carbide and transformed austentite. This gives a hard layer which confers good resistance to wear. The core and necks exhibit a tough grey structure, and the iron of the transition zone is mottled. Compared to grey iron, white chill iron is less soft, strong and incapable of with standing high dynamic stresses, but owing to its greater hardness, has better wear-resistance, and has high compressive strength. It retains a fair proportion of its strength at elevated temperature, for example, in hot rolling . These make excellent work Rollers for two, three and four-high mills, turning out of high grade ferrous and non-ferrous sheet and strip or section. High Alloy Clear Chilled Rollers have proved well suited for the finishing stand of rod and light section mills, for continuous small and medium hot strip mills, and for strip mills of older design.

Application : TMT, Wire Rod, Round & Bar, Plate, Medium and Narrow Strip.

| Hardness | C | Mn | Si | P | S | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|

| 50-60 | 3.00/3.20 | 1.10/1.40 | 0.80/1.10 | 0.15-MAX | 0.06-MAX | 1.00/1.50 | 0.80/1.10 | 0.20/0.35 |

| 60-70 | 3.00/3.20 | 0.60/0.90 | 1.00/1.60 | 0.11-MAX | 0.11-MAX | 1.50/2.00 | 1.00/1.60 | 0.30/0.40 |

| 70-75 | 3.00/3.50 | 0.60/0.90 | 0.70/1.10 | 0.10-MAX | 0.050-MAX | 1.50/3.00 | 1.60/1.90 | 0.40/0.50 |

Adamite Rolls

Adamite Rolls

These Rolls are special hyper-eutectoid steel rolls alloyed with Nickel, Chromium & Molybdenum. The extra Carbon and special alloys give extra wear resistance and strength.

These Rolls undergo a sophisticated multi-stage high temperature Heat – Treatment (Double Annealing followed by tempering cycle) to give the combination of hardness, toughness and wear resistance required for the particular application.

Application : These Rolls are suitable for rolling medium and heavy sections. These rolls are also used for roughing stands of strip mill.

Range of chemical composition :

| Hardness | C | Mn | Si | Ni | Cr | Mo |

|---|---|---|---|---|---|---|

| 40-45 | 1.20/1.40 | 0.60/0.90 | 0.30/0.60 | 0.60-MAX | 0.80/1.10 | 0.25/0.35 |

| 45-50 | 1.40/1.60 | 0.60/0.90 | 0.30/0.60 | 0.60-MAX | 1.00/1.20 | 0.30/0.40 |

| 50-55 | 1.50/1.90 | 0.60/0.90 | 0.30/0.60 | 0.80/1.40 | 1.10/1.30 | 0.35/0.50 |

Spherical Graphite Rolls(SG Rolls)

Pearlitic and Acicular

S.G Iron Rolls are available in a wide range of hardness & composition for a variety of application. These Rolls are essentially an Indefinite Chill type material, but with the Graphite in Nodularform instead offlake and having alloyed with higher % of Nickel & Molybdenum along with Carbon.. The matrix structure varies from Ferrito-Pearlitic, Pearlitic to Bainitic & Martensitic together with different carbide contents and graphite in the form of spheroids/nodules. Some critical grades are heat treated for higher strength. These rolls are very much suitable for the rolling of row products with wide range of applications due to its hardness penetration, good wear resistance and tough necks, this material has become a benchmark.

Application: Roughing and intermediate rolls for slabbing and blooming mills. Roughing, intermediate and finishing for structural mils. Finishing for wire rod and narrow strip mils.

Range of chemical composition :

| Grade | Hardness | C | Mn | Si | P | S | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|---|

| Pearlitic | 40-50 | 3.00/3.20 | 0.30/0.60 | 1.50/2.20 | 0.10-MAX | 0.15-MAX | 1.00/1.40 | 0.20/0.30 | 0.25/0.40 |

| Pearlitic | 50-60 | 3.00/3.20 | 0.30/0.60 | 1.50/2.20 | 0.10-MAX | 0.15-MAX | 1.40/1.80 | 0.20/0.35 | 0.25/0.40 |

| Pearlitic | 60-65 | 3.20/3.50 | 0.60/1.00 | 1.50/2.20 | 0.10-MAX | 0.15-MAX | 1.60/2.50 | 0.30/0.40 | 0.35/0.55 |

| Acicular | 40-50 | 3.00/3.30 | 0.30/0.50 | 1.80/2.30 | 0.080-MAX | 0.015-MAX | 2.00/3.00 | 0.20-MAX | 0.60/0.90 |

| Acicular | 50-60 | 3.00/3.30 | 0.30/0.50 | 1.80/2.30 | 0.080-MAX | 0.015-MAX | 2.00/3.00 | 0.50-MAX | 0.70/1.00 |

| Pearlitic | 60-70 | 3.10/3.50 | 0.50/0.80 | 1.80/2.30 | 0.080-MAX | 0.015-MAX | 2.00/3.50 | 0.50-MAX | 0.80/1.20 |

| Pearlitic | 70-80 | 3.00/3.30 | 0.30/0.50 | 1.80/2.30 | 0.080-MAX | 0.015-MAX | 2.00/3.00 | 0.20-MAX | 0.60/0.90 |

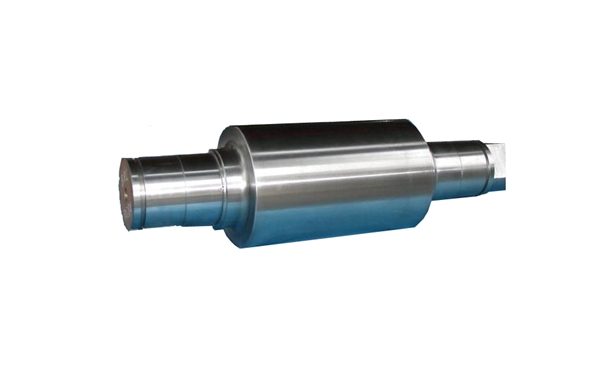

Forged Rolls

Forged Rolls

We manufacture quality range of forged rolls that find application in steel rolling, textile, cement and fertilizer plants. These forged rolls are available in various weights, diameters and thickness to meet varied applications and client’s requirements.

Rolling Mill & Spares

Rolling Mill & Spare Parts

We also Supply and Export of a wide range of Steel Rolling Mill Machinery. These Steel Rolling Machinery are fabricated using premium quality raw material, out of these Mill Machinery find their applications in various industries. We offer these Mill Machinery to our valuable clients at competitive market rates.

We offer Following Product Range in Rolling Mill Machinery :

-TMT Rolling Mill Plant

-Bar Rolling Mill Plant

-Structure Rolling Mill Plant

-Pusher and Ejector

-Gear Box and Pinion Stand

-Hot and Cold Shearing Machine

-Rotary shear and pinch Rolls

-Fly wheels and Pulleys

-Straightening Machine

-2Hi and 3 Hi Mill Stands

-Bearing Chocks and Gear Couplings

-Spindle and couplings

CONTACT US

MOHINDER GOGIA

+91-9417048166

RAKESH GOGIA

+91-9888117361

SAHIL GOGIA

+91-8837751293

Email Us :

tejasavirollsindia@yahoo.co.in

tejasavicastingspvtltd@gmail.com

Address :

TEJASAVI ROLLS INDIA

WORKS – D336, FOCAL POINT, PATIALA.SCO-112, 1ST FLOOR, ABOVE AXIS BANK, URBAN ESTATE PHASE-2, PATIALA.